By

Nana Terra

April 1, 2021

Updated

January 28, 2025

More and more manufacturers note the fragility of relying on skilled talent, access to physical space, and centralised factories to produce goods.

At the same time, sensors, machine learning, robotics, cloud computing and other advanced technologies have proven to increase supply chain resiliency for manufacturers who adopt it.

The COVID-19 pandemic's impact on the supply chain has been reported worldwide, and the sector is crying out for IT talent, innovation and better digital tools.

The APQC's report analyzes the potential disruptions that may occur in different sectors, including the supply chain, which will play a vital role in advancing the global economy.

.png?width=1080&height=1080&name=Leading%20trends%20anticipated%20to%20impact%20supply%20chains%20by%202025%20(1).png)

The digitalisation of the supply chain is a prominent trend, ranking second only to big data and analytics. It is crucial for businesses to be aware of this in order to remain competitive in today's and tomorrow's market.

Technological innovations are changing the way we live, work and behave as consumers. The changes impact business and require that companies rethink the linear operating model of the past to become the networked business of the future.

- From the past to the future

- Challenges and benefits of smart factories

- Good for customers, good for employees and good for your business

- Covid-19: accelerating the future in the manufacturing process

- Jobs in demand

- Are you recruiting tech talent for your manufacturing process?

From the past to the future

To boost productivity and cost-saving, manufacturing 3.0 focused on repeatable processes from product development, manufacturing, and logistics. Today, though, rapid digital advances mean manufacturers can go to the next level of performance.

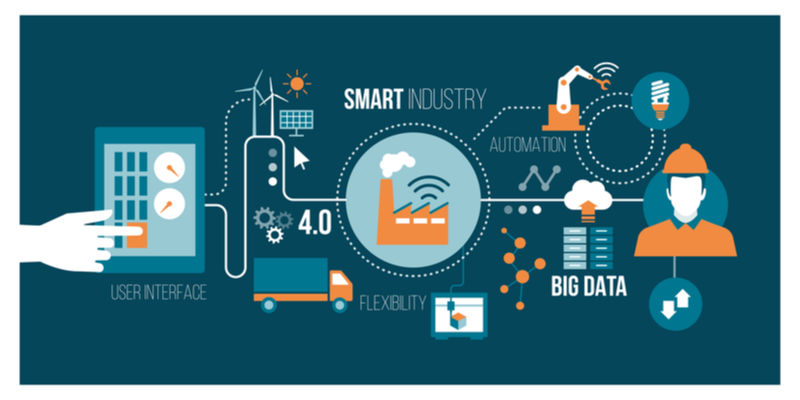

Now, the industry is based around ecosystems that are data-driven, cloud-enabled and platform-centred. Before presenting the challenges and benefits of digital manufacturing, it is important to understand what it means.

It is the application of computer systems to manufacturing services, supply chains, products and processes. Digital manufacturing technologies link systems and processes across all areas of production to create an integrated approach to manufacturing, from design to production and on to the servicing of the final products.

Challenges and benefits of smart factories

Source: elenabsl/Shutterstock

Source: elenabsl/Shutterstock

Artificial intelligence (AI)-powered robots, 3D printing, the Internet of Things (IoT), big data, automation, and much more. There’s a world of advanced digital manufacturing technologies. However, digital transformation can present two fundamental challenges.

The first one is related to changing the mindset towards a digital world, moving away from the traditional model of supply chain management, manufacturing, and distribution.

The second is added cybersecurity risk. With so many people online accessing and sending data, an important question comes to the fore about the digital thread. How to ensure cybersecurity in times of excessive use of digital tools?

All technology implementations should begin with a plan that includes cybersecurity. A sound cybersecurity plan not only helps manufacturers identify and improve current security protocols; but also, positions them to manage future risk.

If there is not an innovation culture in your company, maybe enlisting outside expertise can help. They can provide guidance and training to leverage knowledge, skills, and abilities in digital manufacturing systems, such as the following:

- AI/machine learning

- Advanced data analytics

- Augmented/virtual reality

- Automation

- Cloud computing

- Digital twins

- Sensors / IoT

- Wireless infrastructure

- Zero-trust models

- PLC programs

- Camera systems

Despite the challenges, there are also great opportunities coming from industry 4.0. It can deliver better experiences for customers and employees while boosting productivity and efficiency.

Information technology provides you with the right data to make better decisions, reduce time to market, and create a joined-up manufacturing process that unites digital tools with the physical manufacturing execution.

At first glance, it may seem that technology would replace humans; but this is not true. Together, humans plus machines deliver superior outcomes to the business.

Good for customers, good for employees and good for your business

Source: 13_Phunkod/Shutterstock

Source: 13_Phunkod/Shutterstock

Here are some advantages of digital manufacturing:

- Technologies such as data science can enhance and streamline customers' buying and after-sales experiences.

- All the team can see and work simultaneously if an event occurs in the supply chain, reducing and avoiding risks.

- The combination of data and mobile technologies makes problem-solving faster and smarter, which contributes to more informed decision-making.

- Several activities can be done in a remote model, no matter where you are located.

- Empower employees at all levels with data by helping them stay informed and engaged beyond augmenting their skills and value.

- Increase operational efficiency and agility.

- Reduce downtime.

- Improve the ability to predict and adjust to facility and supply changes.

- Allows for the manufacturing process to be created virtually before it is implemented physically, saving time and money.

Covid-19: accelerating the future in the manufacturing process

Source: PopTika/Shutterstock

Source: PopTika/Shutterstock

Before the COVID-19 pandemic, the process of digitising manufacturing was already on the rise in many companies around the world. But after the pandemic, investing in innovation and adapting to the future became a requirement.

According to the Copenhagen Institute for Futures Studies, organisations that prioritise strategies to combine economy and productivity will be better prepared to overcome the crisis and resume growth.

One of the smartest ways to do this is to invest in innovation. But what does it mean for the businesses? Be more digital, interconnected, integrated, humanised and sustainable from the shop floor and the engineering department to the CFO's office.

There are still many uncertainties about the future of work after COVID-19. The global coronavirus crisis anticipated a technological explosion. The world changed...

And now, companies need to adapt to this future that has already begun, where automation, technology and remote monitoring will be the protagonists of post-crisis reconstruction.

Jobs in demand

According to MIT's recent report, The Work of the Future: Building Better Jobs in an Age of Intelligent Machines, automation is not just replacing existing work but creating new and better, higher-paying jobs for factory workers.

Also, we'll see increased investment to empower the workforce, through retraining and access to STEAM education.

There are plenty of opportunities for tech talent in the manufacturing industry. Key roles in demand include:

- Computer Vision Engineer

- AI Machine Learning Engineer

- PLC Programmers

- RD Engineers/Managers

- Software Developers

- Automation Engineers

To thrive in the age of automation some soft skills are required, such as:

- Leadership

- Communication

- Problem-solving

- Intuition and logic

- Adaptability

If you are looking for a job in this sector, we can help with your job search.

Are you recruiting tech talent for your manufacturing process?

The need for tech talents specialists has grown fast in recent years. It’s becoming harder to fill roles, train new staff and build a workforce prepared to contribute to the future of the industry.

If you are looking for new talent, Airswift can help you. With over 60 offices worldwide, 1,000 employees, and 9,000 contractors, we are the agency of choice for the top manufacturing businesses.

When you need manufacturing talent, a specialist recruiter can help you to do the following:

- Source the best in local and international talent.

- Identify talent maps and plan your project accordingly.

- Ensure your project runs smoothly and on budget.

We already have access to those networks and will source the best professionals for your team.